E-Coating Defects . Finding what causes defects in ecoat systems. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Great dane powder coating’s team of electrocoating experts have.

from www.mdpi.com

Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Great dane powder coating’s team of electrocoating experts have. Finding what causes defects in ecoat systems. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank.

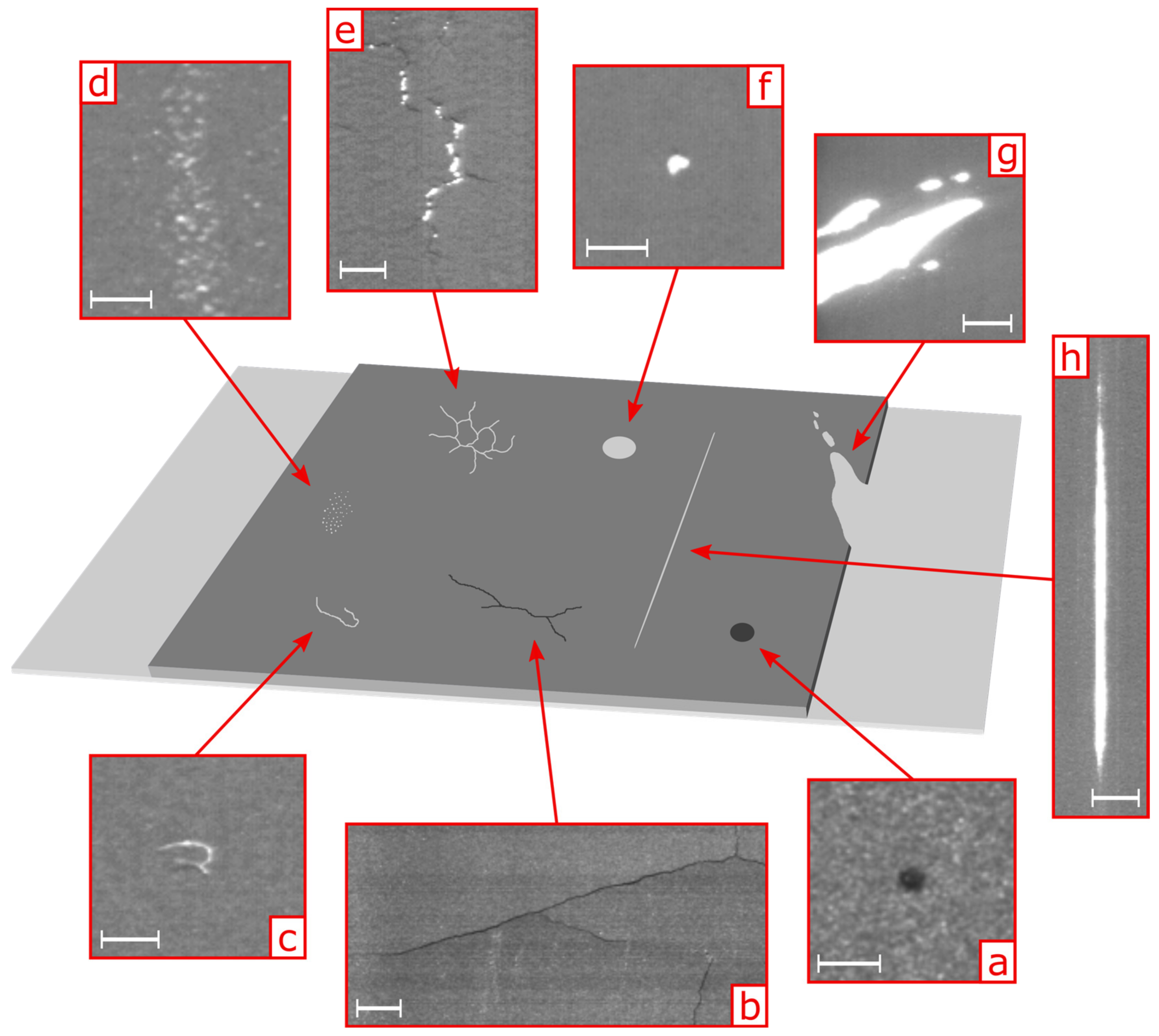

Batteries Free FullText Coating Defects of LithiumIon Battery

E-Coating Defects Finding what causes defects in ecoat systems. Finding what causes defects in ecoat systems. Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Great dane powder coating’s team of electrocoating experts have. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine.

From fitzsatlas.com

Fitz's Atlas of Coating Defects and Surveys E-Coating Defects The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Great dane powder coating’s team of electrocoating experts. E-Coating Defects.

From www.mdpi.com

Batteries Free FullText Coating Defects of LithiumIon Battery E-Coating Defects The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. Finding what causes defects in ecoat systems. Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Great dane powder coating’s. E-Coating Defects.

From esst.cip.com.cn

Defects detection and recognition of lithium battery electrode plate E-Coating Defects The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Finding what causes defects in ecoat systems. Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. Continuous conformance and. E-Coating Defects.

From www.fitz-coatings.com

Fitz Coatings » Identifying common coating defects E-Coating Defects Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. Great dane powder coating’s team of electrocoating experts have. Finding what causes defects in ecoat systems. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. The present review examines the different types of defects associated with surface. E-Coating Defects.

From www.pharmapproach.com

Defects in Film Coating Process Causes and Possible Solutions E-Coating Defects Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. Finding what causes defects in ecoat systems. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Great dane powder coating’s. E-Coating Defects.

From www.thequalityguide.com

Coating Faults Common Issues and Solutions The Quality Guide E-Coating Defects Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. Great dane powder coating’s team of electrocoating experts have. Broken. E-Coating Defects.

From materean.com

Names of coating/surface defects Paul Wu's Blog E-Coating Defects Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Finding what causes defects in ecoat systems. Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. The present review examines. E-Coating Defects.

From www.mcipaint.com.my

Good Painting Procedures Chapter 3 Paint Defects MCIPAINT E-Coating Defects Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Finding what causes defects in ecoat systems. Great dane powder coating’s team of electrocoating experts have. The first step in solving defects in ecoat, says. E-Coating Defects.

From reliantfinishingsystems.com

Resolving Powder Coating Pinhole Problems Reliant Finishing Systems E-Coating Defects Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. Great dane powder coating’s team of electrocoating experts have. Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. The present. E-Coating Defects.

From www.researchgate.net

Surface defects of steel plate. Download Scientific Diagram E-Coating Defects Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. Great dane powder coating’s team of electrocoating experts have. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. Finding what. E-Coating Defects.

From www.researchgate.net

(PDF) Coating Defects of LithiumIon Battery Electrodes and Their E-Coating Defects Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. Finding what causes defects in ecoat systems. Broken or misaligned. E-Coating Defects.

From www.mdpi.com

Batteries Free FullText Coating Defects of LithiumIon Battery E-Coating Defects The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Great dane powder coating’s team of electrocoating experts have. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. Broken. E-Coating Defects.

From www.rheologylab.com

Coating Defects How Rheology Can Help Rheology Lab E-Coating Defects Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. Great dane powder coating’s team of electrocoating experts have. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Finding what. E-Coating Defects.

From www.slideshare.net

coating defects E-Coating Defects Great dane powder coating’s team of electrocoating experts have. Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Finding what causes defects in ecoat systems. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. The first step in solving defects in ecoat, says. E-Coating Defects.

From www.slotdies.com

4 Steps To Resolving Coating Defects E-Coating Defects Finding what causes defects in ecoat systems. Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. The first step in solving defects in ecoat, says axalta’s joe subda, is to determine. Great dane powder coating’s team of electrocoating experts have. The present review examines the different types of defects associated with surface. E-Coating Defects.

From www.slideshare.net

coating defects E-Coating Defects Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Finding what causes defects in ecoat systems. Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. The. E-Coating Defects.

From www.slideshare.net

coating defects E-Coating Defects Finding what causes defects in ecoat systems. Broken or misaligned eductors can cause appearance defects in production and dead zones in the paint tank. Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. Great dane powder coating’s team of electrocoating experts have. The present review examines the different types of defects associated. E-Coating Defects.

From www.inventionh.com

Common Conformal Coating Issues Invention House E-Coating Defects Finding what causes defects in ecoat systems. Continuous conformance and validation of automotive oem specification requires protocols that involve testing the chemical and physical. The present review examines the different types of defects associated with surface coatings, their significant causes, and the. Great dane powder coating’s team of electrocoating experts have. Broken or misaligned eductors can cause appearance defects in. E-Coating Defects.